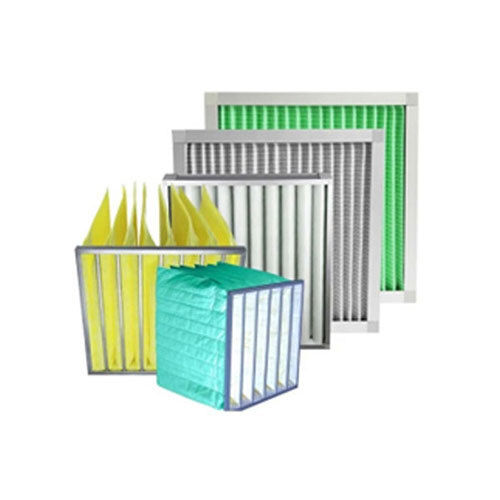

Panel Filters

Price 850 INR/ Piece

Panel Filters Specification

- Efficiency (%)

- 99.9%

- Usage

- Industrial

- Condition

- New

- Material

- SS, Alluminium, GI, Cardboard

- Size

- As per your design

- Product Type

- Panel Filters

- Construction

- Panel Filter

- Color

- Different colors available

- Shape

- Square

- Feature

- High Filtration Efficiency, Easy Installation & Replacement

Panel Filters Trade Information

- Minimum Order Quantity

- 100 Pieces

- FOB Port

- hajira,porbandar

- Supply Ability

- 15 Pieces Per Day

- Delivery Time

- 15 Days

- Packaging Details

- as per box

About Panel Filters

Versatile Material Options for Every Industry

Choose from stainless steel, aluminium, GI, or cardboard panel filters to suit diverse applications, from industrial spaces demanding durability to cost-effective commercial uses. Our wide range of materials enables us to cater to unique filtration requirements, guaranteeing optimal performance and longevity.

Tailored Solutions and Global Reach

We specialize in providing panel filters in sizes designed as per your specifications. As established exporters, importers, manufacturers, suppliers, and traders based in India, we offer timely delivery and end-to-end support for clients around the world, ensuring you receive exactly what you need for your filtration systems.

FAQ's of Panel Filters:

Q: How are panel filters with materials like SS, Aluminium, GI, and Cardboard used in different industries?

A: Panel filters made from stainless steel, aluminium, GI, and cardboard are employed in environments ranging from hospitals and cleanrooms to factories and offices. The choice of material depends on factors like durability, corrosion resistance, and required filtration efficiency.Q: What sizes are available for your panel filters and can they be customized?

A: Our panel filters are available in a range of sizes, custom-made according to your design requirements. Simply provide your specifications and we will manufacture filters that perfectly fit your application.Q: When should panel filters be replaced or maintained for optimal performance?

A: It is recommended to inspect and replace or clean panel filters regularly, depending on the air quality and environmental conditions. Most facilities benefit from quarterly maintenance, but high-dust environments may require more frequent checks.Q: Where can your panel filters be installed?

A: Our panel filters are suitable for HVAC systems, air handling units, and dust collection systems in commercial, industrial, and residential settings. Installation is straightforward and our team can provide guidance if needed.Q: What is the process of ordering and sourcing panel filters from your company in India?

A: You can order our panel filters by sharing your required specifications and quantity. As an exporter, importer, manufacturer, and supplier, we handle manufacturing, quality checks, packaging, and international shipping, ensuring a seamless process for local and overseas clients.Q: How do panel filters benefit air quality and system efficiency?

A: Panel filters trap dust, pollen, and other airborne particles, preventing them from entering sensitive equipment or living spaces. This not only improves air quality but also enhances the performance and lifespan of HVAC systems by reducing buildup and maintenance requirements.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Air Filters Category

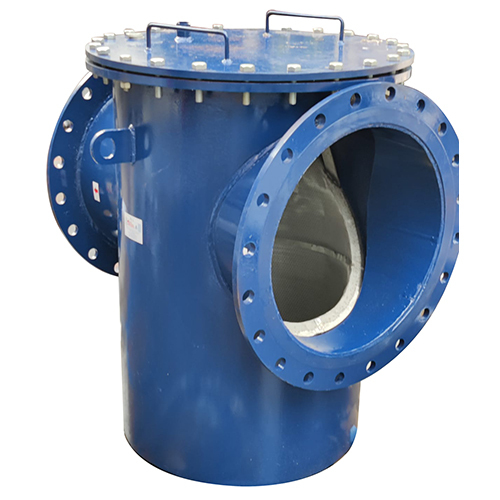

Basket Filter Strainer Bucket Type

Price 250 INR / Piece

Minimum Order Quantity : 100 Pieces

Efficiency (%) : Up to 97%

Feature : High dirt holding capacity, easy to clean, robust construction

Condition : New

Material : Stainless Steel

Air Filter Elements

Price 600 INR / Piece

Minimum Order Quantity : 100 Pieces

Efficiency (%) : 99.9%

Feature : High Filtration Efficiency, Easy Installation & Replacement

Condition : New

Material : PU, SS, MS or Imported Submicronic Glassfibre

Inlet Hepa Filter

Price 5000 INR / Piece

Minimum Order Quantity : 100 Pieces

Efficiency (%) : 99.9%

Feature : High Filtration Efficiency, Easy Installation & Replacement

Condition : New

Material : Stainless Steel

Panel Type Air Filter

Price 250 INR / Piece

Minimum Order Quantity : 100 Pieces

Efficiency (%) : 99.9%

Feature : Good Qualty, High Filtration Efficiency, Easy Installation & Replacement

Condition : New

Material : MS

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS